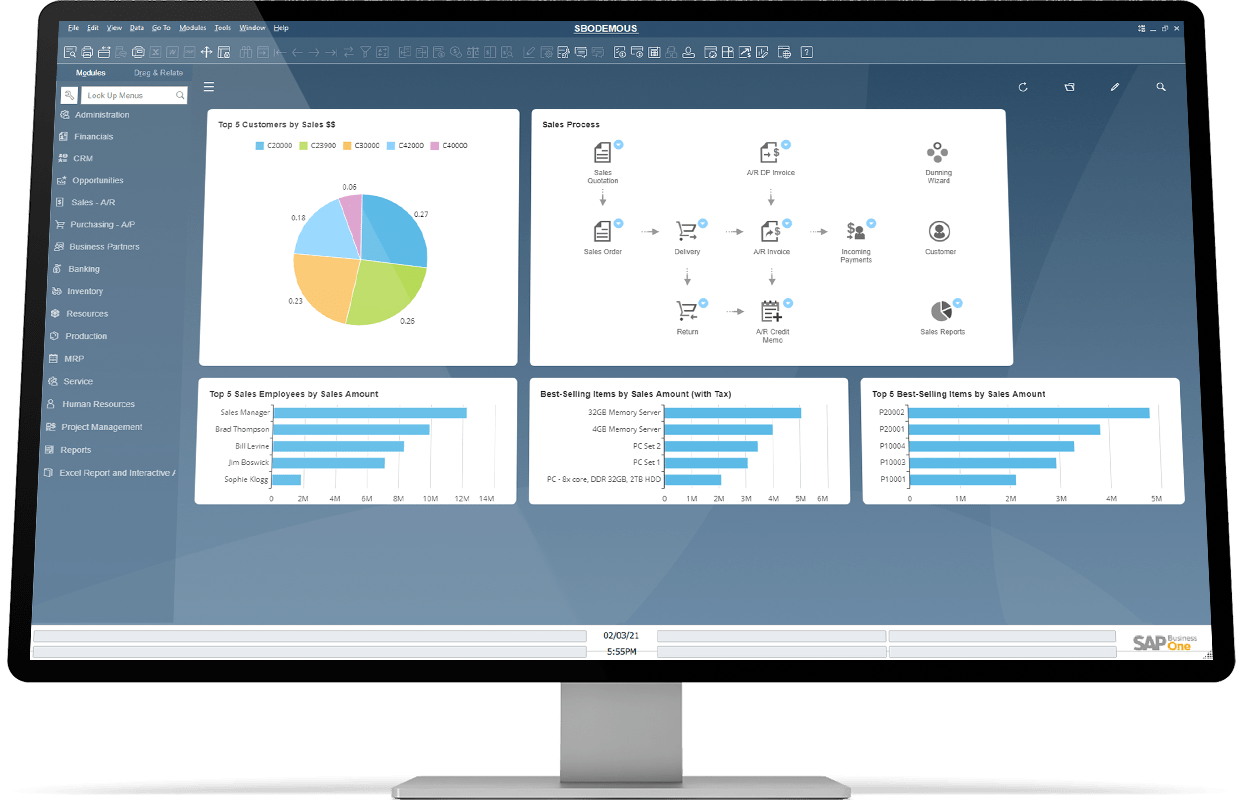

A key requirement of most manufacturing organisations is the ability to plan production for looking at demand and supply of finished goods, raw materials and considering capacity constraints for labour, machine and resource availability.

Planning production runs requires an assessment of labour, machine time and other resource bottle necks for optimized production scheduling.

Resource planning has the ability to manage capacity for labour, machinery and “other” capacity constraints.

Go to the Resources module and click on the Resource Master Data menu item.

In resource master data we can capture master data associated with our machines and labour or “other” capacity constrained items for manufacture

- Resource allocation is worth a special mention as the different resource allocation methods will determine the timing of the resource allocation to the production schedule.

- The automatic schedule will try and schedule the production order on available timeslots (available resource) prior to the required date

- If “on due date” is selected the system will try and schedule the production order on the due date.

- Other information to be completed on the resource master data screen in SAP Business One includes:

Capacity data by warehouse

Planning data – daily capacity for machines, labour and other equipment. In the example below the capacity that has been configured for a packaging machine based on uptime available for the machine Monday through Friday (2 shifts on Monday through Thursday) with some downtime on Friday for machine maintenance.

Properties, attachments and remarks can be added to the resource master data.

- To review resource capacity go to the resource capacity menu item

- We can also narrow down your capacity constraints by warehouse, resource code, and resource group and resource type.

- This planning tool will allow you to review the factory capacity constraints.

SAP Business One – Resource Capacity Planning:

If we do a brief analysis of the data above we can see that there is a capacity constraint issue for the packaging machine on the 3rd of February

We have 16 hours of machine time available and 19 hours committed , this leaves the factory with -3 hours available on the 2nd February

Our production planner now has a clear view of the fact that there is a capacity constraint on the packaging machine and can start to plan accordingly

By clicking on the “Committed – 19 hours” section of the report SAP Business One will drill down to the production order/s which are committed

The production manager can then re-schedule this production or can increase the capacity on that day